Limestone processing

Key words:

Category:

解决方案

Brief Introduction:

Applications:

Suitable Material:

Limestone processing

Limestone

LimestoneLimestone is mainly formed in the shallow sea environment. The main chemical composition of limestone is that calcium carbonate is easily dissolved, so stone forests and karst caves are formed in limestone areas, which are called karst topography. The main mineral composition of limestone is calcite. Mineral particles and crystal structures are rare, and the surface is smooth and small-grained. The colors are black, gray, white, yellow and brown. Limestone contains lime formed from seawater, hence the name. The main component is calcium carbonate.

Lime includes quicklime and slaked lime. The main component of quicklime is CaO, which is generally lumpy, pure white, and light gray or light yellow when it contains impurities. Quicklime absorbs moisture or adds water to become slaked lime. Slaked lime is also called slaked lime, and its main component is Ca (OH) 2. Slaked lime is prepared into lime slurry, lime plaster, lime mortar, etc., which are used as coating materials and brick and tile adhesives.

Application field

Limestone can be directly processed into stone and fired into lime. Lime includes quicklime and slaked lime. The main component of quicklime is CaO, which is generally lumpy, pure white, and light gray or light yellow when it contains impurities. Quicklime absorbs moisture or adds water to become lime, and slaked lime is also called slaked lime. Its main component is Ca (OH) 2. Slashed lime is prepared into lime slurry, lime paste, lime mortar, etc., which is mainly used in cement, glass, ironmaking, steelmaking, chemical industry, etc.

Limestone is fired and processed into pure powdered calcium carbonate, which can be used as fillers for rubber, plastics, paper, toothpaste, cosmetics, etc. In agriculture, quicklime is used to prepare pesticides such as lime sulfur mixture and Bordeaux liquid; the application of slaked lime in the soil can neutralize the acidity of the soil, improve the structure of the soil, and supply the calcium needed by plants.

Processing technology

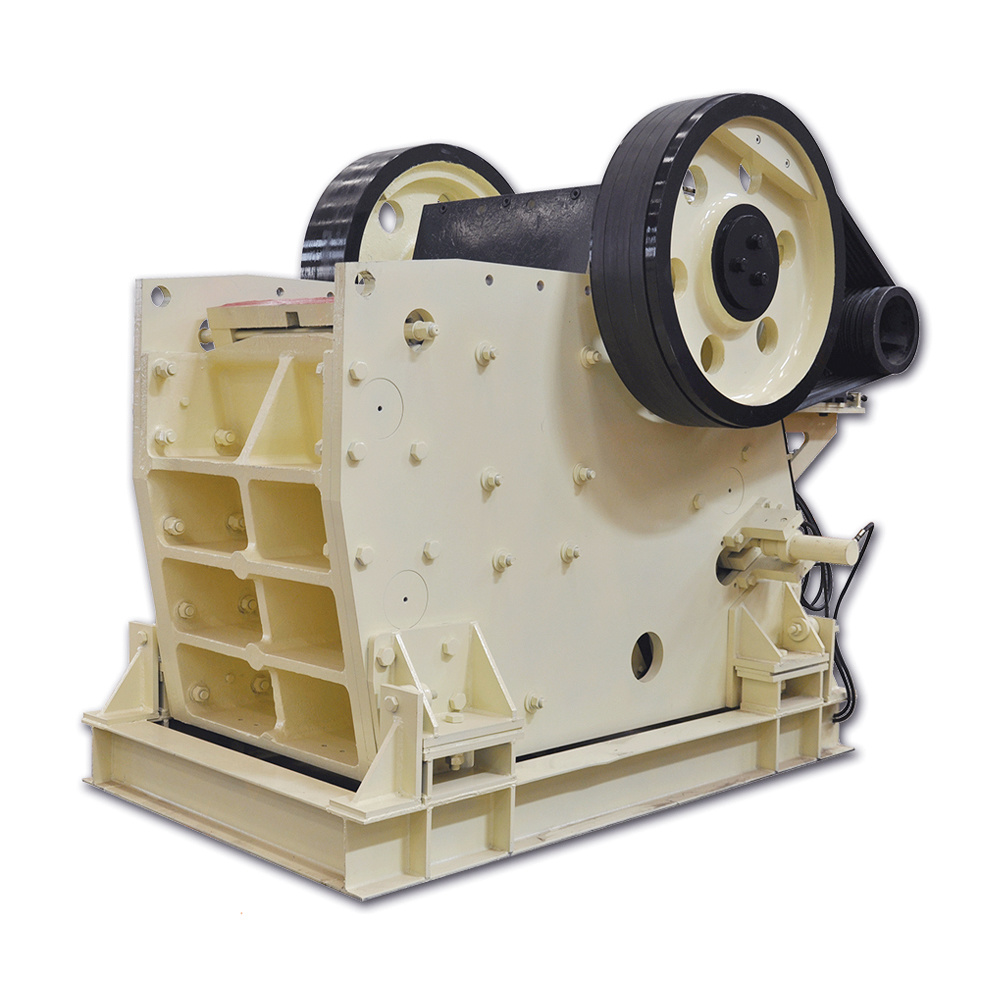

The stone is initially broken by jaw crushing, and then entered into counterattack crushing for further crushing. The second crushed stone is sent to the vibrating screen to screen out stones of different specifications, and the stones that meet the particle size requirements are sent to the finished material pile. The stones larger than the size of the screen are returned to counterattack crushing for re-crushing. This production line has high crushing efficiency, simplifies the production process and saves investment. The specific process configuration needs to be analyzed according to the actual situation on site. Welcome to visit and exchange.

PREV

NEXT

PREV

NEXT

Leave A Message